TOYOTA MATERIAL HANDLING NEDERLAND, EDE, THE NETHERLANDS

Architect: Rempt van der Donk Architecten │ Client: Bruil Bouw │ Project date: 2013 | Photography: Menno Emmink and others.

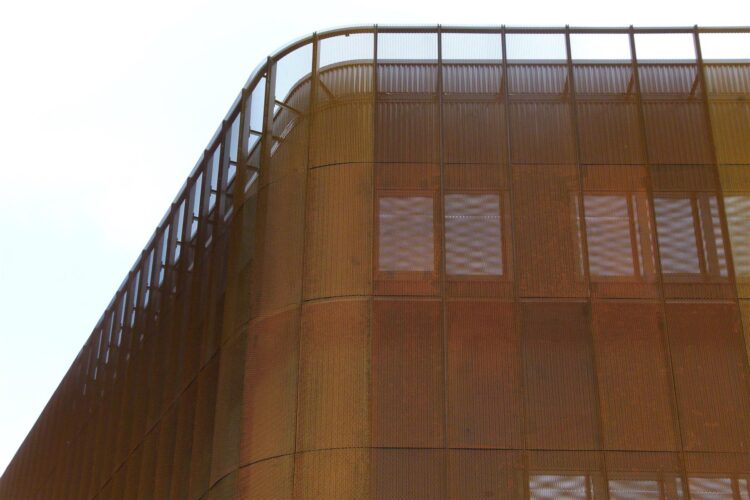

Product: MD Strekmetaal / Corten

Type: MD Fils21 with an adjusted pattern

Materiaal: Steel

Surface treatment: Hot-dip galvanized and powder coated 60µm in standard RAL-colour

Weather-Resistant Façade for Toyota

A familiar sight along Dutch motorways is the prevalence of buildings that combine office and warehouse functions within business parks. This typical image is precisely what the architect aimed to avoid in the design of the new office and warehouse for Toyota Material Handling Netherlands in Ede. Instead, the goal was to create a unified and cohesive whole. The building, located along the A12 motorway, has been clad by Metadecor with a façade that wraps around the structure like a second skin. The division between office and warehouse on the motorway-facing side is concealed behind a veil of MD Expanded Metal in Corten steel.

A robust façade in corten steel

The building was designed by Rempt van der Donk Architects, and Metadecor was commissioned to create the façade. A large window has been integrated into the weather-resistant steel (Corten steel) façade, offering passers-by on the motorway a glimpse into the company within.

The expanded metal veil functions as a sun screen, reducing direct solar gain and heat build-up within the building. It also protects the underlying façade and windows from excessive soiling. Despite its protective function, the expanded metal does not obstruct views from the interior to the outside. Corten steel is considered sustainable due to its maintenance-free nature and recyclability.

Smart construction

A total of 2,700 m² of MD Expanded Metal, type MD Fils21 with a customised pattern (similar to MD Fils5), was used. The veil’s structure stands on its own independent foundation, positioned 60 centimetres from a basic structural façade. Metadecor also provided the support structure and access gratings for the façade.

A UNP profile is mounted on the outer cavity wall structure, onto which T-beams are fixed. These beams connect to vertical steel box profiles that rest on individual foundation blocks. The façade panels are bolted through slotted holes in the steel uprights, allowing for on-site adjustments during installation.

The reddish-brown patina of the Corten steel façade aligns well with the municipality’s visual quality plan for the business park.

The reddish-brown patina of the Corten steel façade aligns well with the municipality’s visual quality plan for the business park.

Building extension in 2020

Several years after the initial façade was completed, Toyota expanded the building. Architect Rempt van der Donk was again engaged for the design, and Metadecor was commissioned to produce the façade cladding for the extension. Notably, this was not merely an addition: the existing side façade cladding was dismantled and reinstalled in conjunction with the extension. A practical example of a circular façade. The new section was built using the same STR116 mounting system as the original. The combination of MD Expanded Metal with Corten steel and the precise, systematic assembly complements the building’s robust appearance.